No two modernisations are the same, this is why we address every customer need individually.

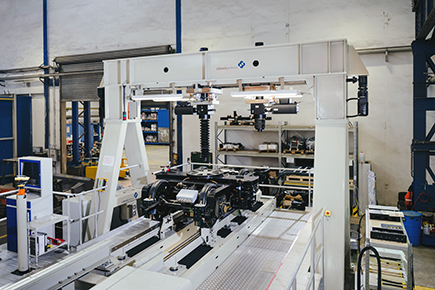

If the customer does not have a ready modernisation concept, we develop the project together until the concept is finalised. In the process, the necessary materials including all of the documents relevant for the approval are obtained directly from a single source. All of the work from the dismantlement to the integration of the modernised bogies in the vehicle is documented fully, adapted to our customers and always agreed in advance. We have the necessary equipment (washing plant, appropriate welding certification (CL1), blast cabinet, paint areas and crane installations) in order to carry out a bogie refurbishment completely independently in-house. Appropriate test equipment (cleanliness measurement, pressure test, function test, ISO measurement etc.) also provides the operator/TAB with full verification.

- Full dismantlement and assembly of the bogies

- Weld repair of the bogie frames

- Repainting of the bogie frames

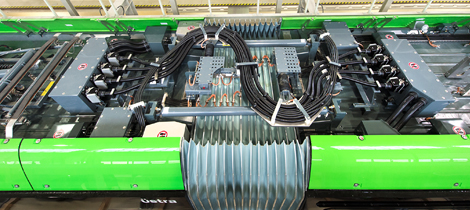

- Complete rewiring of the electronic components

- Tube replacement in hydraulic systems

- Regeneration of clasp brakes

Download product sheet as PDF

Our competences for vehicle interior modernisation:

- Passenger seats and handrails

- Insulation and soundproofing

- Passenger compartment heating, thermostatically controlled

- Flooring

- Interior panelling

- Lighting

- Driver compartment back panels and doors

Here too: it can be said that no two modernisations are the same, this is why we address every customer need individually. We design and construct assemblies taking into account the requirements of EN 12663. We have already produced, refurbished and assembled numerous assemblies for our customers and then installed them in the vehicle in accordance with EN 50215.

We develop the passenger seat in line with the design concept of our customers.

- Seat bases in line with design concept (thermoforming panel parts)

- Corrosion-resistant seat frames

- Handrails

- Shell construction in the area of side wall panelling

- Fire prevention in accordance with EN 45545 HL 1

- Absorption of forces from vehicle operation in accordance with EN 12663 and UIC 566

- Lighting examples for the modernisation of your interior

Our competences for vehicle exterior modernisation:

- Driver and passenger air conditioning

- Replacement of passenger compartment doors

- Installation of folding ramps

- Lighting

- Panes

- Replacement of automatic / electric transition

- Painting

Here too: Here, too, it can be said that no two modernisations are the same, this is why we address every customer need individually. We design and construct assemblies taking into account the requirements of EN 12663. We have already produced, refurbished and assembled numerous assemblies for our customers and then installed them in the vehicle in accordance with EN 50215.

No two modernisations are the same, this is why we address every customer need individually. We design and construct assemblies taking into account the requirements of EN 12663. We have already produced, refurbished and assembled numerous assemblies for our customers and then installed them in the vehicle in accordance with EN 50215.

As well as building new vehicles, HeiterBlick can also refurbish (retrofit) fleet vehicles as required by upgrading components. We also sell body shells.

Our high-quality components such as bogies and coach bodies fit perfectly into any other manufacturing processes that may be required so that line operation may resume quickly. We have completed many such upgrading projects in recent years.

One example is the Pöstling mountain railway in Linz, Austria, which is considered one of the world's steepest long-distance adhesion railways.

Or the replica panoramic motor car for the rack railway along Lake Geneva in Switzerland between Montreux and Glion known as the ‘Marmot Line’. We supplied 36 new motor bogies with a 1,009 mm gauge to a transport company in the Bulgarian capital of Sofia, allowing 18 Tatra T8M vehicles to be upgraded.

We would be glad to help with your own upgrading projects and give you all the information you need about our extensive range of goods and services.

HeiterBlick GmbH

Niemeyerstraße 2-5

04179 Leipzig

Germany

Managing Directors:

Samuel Kermelk

Bernd Flaskamp